Compressed Air Audit Services

Compressed air is move to higher level of energy consumption in industries ad also become a ” The fourth utility”-“Your most expensive utility”-“Eight times more expensive than electricity”.

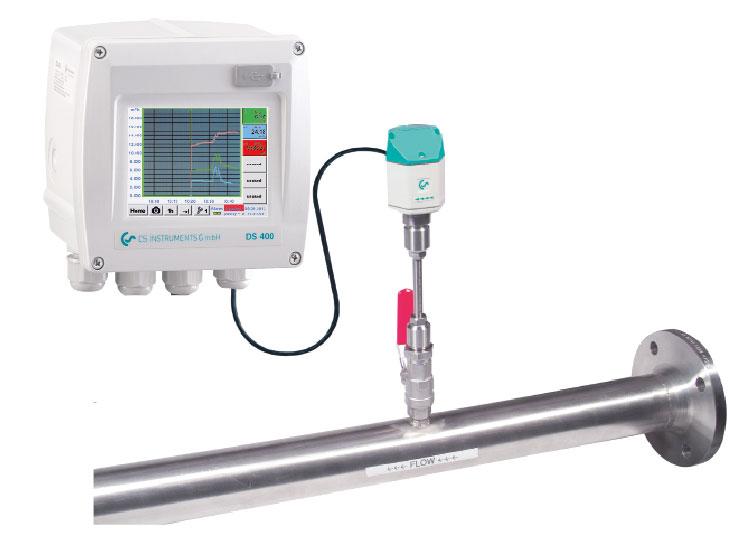

The easiest but potentially the most expensive was to improve your compressed air operations is to hire someone to do a compressed air audit at your plant. A team of experienced , professional compressed air auditor will visit your plant, spend some days to measuring pressures and examining your system, and give you a lot of inefficiencies of your compressed air.

Ir hasn’t been observe that many people focus on initial cost of compressors. they often forget to factor in the cost of operating the machine over the long run, If ay issue within a system can reduce its efficiency , wasting compressed air and also electricity and thereby costing you more money.

Companies may be also hesitant to spend a lot of money on energy audits, especially when they have little understanding of the true possible savings in their system. The objective of our company is to help the understand the importance and benefits of compressed air audit; not only with low audit cost and also their production lines will operate more efficiently as well.

Air Leakages

The majority of leakage is hard to find out. Air leakage of 1.9 mm and lower in diameter is not audible to human ear. Only one air leakage wastes energy costs up to 13,000 units per year. Often there may occur hundreds of leakages in a plant and owner is not aware of it.

FAD

Normally the actual flow of compressor goes 70 % to 90 % of total rated flow. There may a number of causes and need to find it out

Corrosion

Corrosion is one of the major causes for degrading performance of steel pipes in compressed air system. Corrosion is the gradual loss of metal surface and cause of poor quality of production.